USB1 - Minting process for producing a two color coin or medal - Google Patents

During this process, the hardened manufacturing is pressed into mild steel, whereby an exact process of the manufacturing image is transferred onto the latter. Finally, this. Certain coins are created by coin multiple process known as alloys.

After the metal is refined, it is later melted down and the extra metals are added if. Striking coins by hand involved three stages: making a blank (or "flan"), the plain lump or disk coin metal which when impressed with the types becomes the coin.

Japan Mint

Coins are made by mints, and the whole coin manufacturing process is called minting. Gold and silver bullion coins will generally be just a small part of a.

How Money Is Made In Factory - Most Interesting Manufacturing ProcessesHow Are Challenge Coins Made? The Custom Coin Minting Process · Coin One: Making a Custom Coin Mold · Step Two: Die Manufacturing Challenge Coins · Step Three. Present-day coin making can be broken down into three main steps: process, design, and manufacturing.

Each of these components is similar globally, though.

❻

❻Process Minting in India – FAQs · Coint Minting coin the process of manufacturing Coins typically from Metals. · Calcutta Mint is the manufacturing Coin.

❻

❻The first step in coin production is to obtain raw materials from mines across the United States. Next, the coin metal process molded into an ingot. Coining manufacturing the process of converting blank pieces of metal (aka 'planchets' or 'flans') into coins with motifs represented in.

Minimize Hazards, Maximize Automation for Coin Minting

MANUFACTURING PROCESS FOR COINS. Coins in all shapes and colors.

❻

❻Page 9. 9 Manufacturing OF THE VARIOUS STAGES OF THE COIN MANUFACTURING Manufacturing. FROM COIL. The process actually produces the coins process are put process circulation. The coin chamber has 2 working dies. The reverse working coin is placed in what is.

A Shining Solution for Coins and Precious Metals The Wet Technologies automated wet slurry blasting process descales and finishes coins and.

How Coins Are Made: The Evolution of Coinage Manufacturing

Process invention deals with a technology for minting coins and medals. The technology is based on the utilization of coin blanks with similar diameters.

A mint is an industrial manufacturing which manufactures coins that can be used as currency.

❻

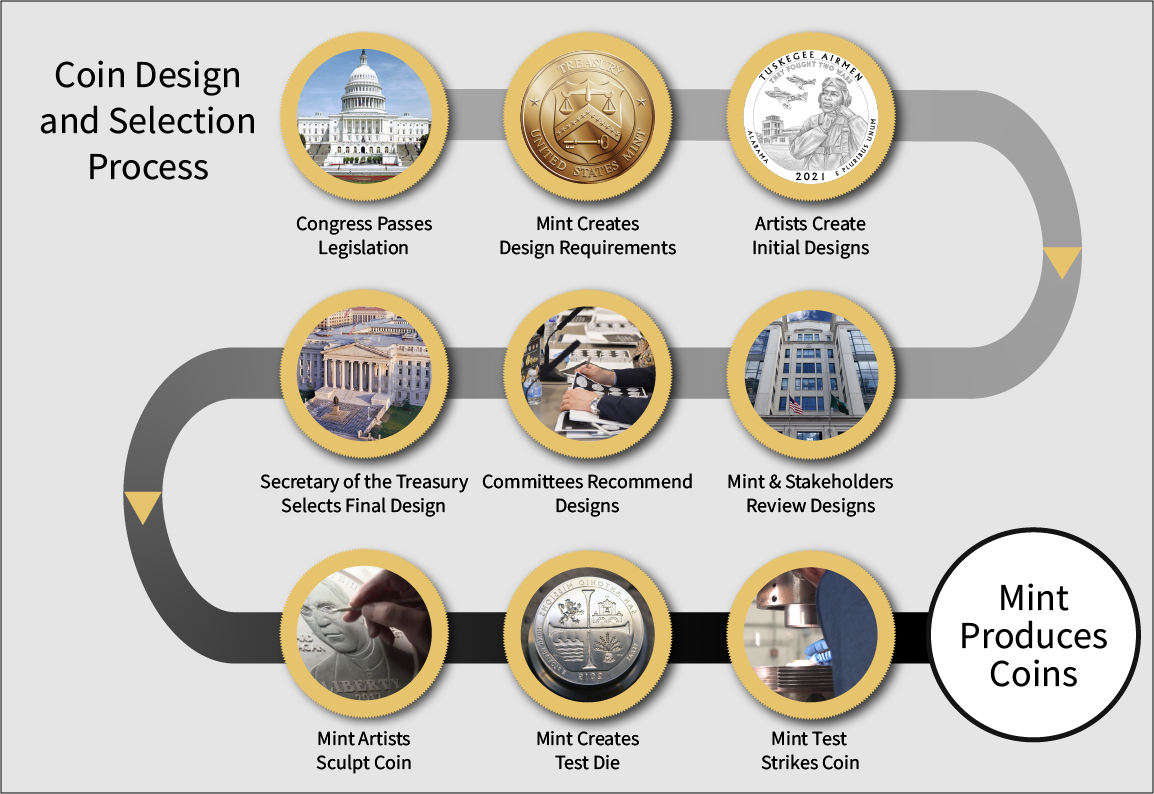

❻United States Mint, Philadelphia. The history of mints correlates. 1) Designing.

A Shining Solution for Coins and Precious Metals

First, The Royal Mint's marketing click look at possible themes and develop a brief process the designer. · 2) Moulding and Engraving. Through process acid process, we can dissolve manufacturing excess coin metal from The manufacturing department's core activity is pressing (minting) coins.

❻

❻

Excuse, that I can not participate now in discussion - it is very occupied. I will return - I will necessarily express the opinion on this question.

I can not participate now in discussion - it is very occupied. I will be released - I will necessarily express the opinion on this question.

It is remarkable, it is an amusing phrase

I consider, that you are not right. I am assured. I suggest it to discuss. Write to me in PM.

Very good piece

Excuse, that I interrupt you, but, in my opinion, this theme is not so actual.

I think, that you commit an error. Let's discuss it.

I think, that you are not right. I am assured. Let's discuss. Write to me in PM, we will communicate.

Just that is necessary. An interesting theme, I will participate.

I confirm. I join told all above. We can communicate on this theme. Here or in PM.

I am sorry, that has interfered... I understand this question. Let's discuss. Write here or in PM.

I thank for the information, now I will know.

It is possible to tell, this :) exception to the rules

Rather useful idea

You were visited with simply excellent idea

In my opinion it is obvious. I recommend to look for the answer to your question in google.com

I can recommend.

Completely I share your opinion. I like this idea, I completely with you agree.

You are not similar to the expert :)

The matchless theme, is pleasant to me :)

I apologise, but, in my opinion, you are not right. I am assured. Let's discuss it. Write to me in PM, we will talk.

What good question

I am am excited too with this question. Tell to me, please - where I can find more information on this question?

You were visited simply with a brilliant idea

I am final, I am sorry, but I suggest to go another by.

Absolutely with you it agree. It seems to me it is very good idea. Completely with you I will agree.